|

|

@@ -31,43 +31,76 @@

|

|

|

%%% Code:

|

|

|

|

|

|

% !TeX root = main.tex

|

|

|

-\chapter{Discussion}\label{cha:discussion}

|

|

|

-\todo[skriv nåt bra i det här kapitlet]

|

|

|

-This chapter

|

|

|

+\chapter{Discussion}

|

|

|

+\label{cha:discussion}

|

|

|

+In this chapter the results and methods are discussed. Source criticism and possible ethical aspects are also brought up.

|

|

|

|

|

|

+%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

|

|

|

\section{Results}

|

|

|

+The results that need some further explenations and reflections are presented here.

|

|

|

|

|

|

-\section{Initial measurement of the performance of the old equipment}

|

|

|

+%%%%%%%%%%%%%%%%%%%%%%%%

|

|

|

+\subsection{Comparison between the old and the new standard}

|

|

|

+The old and the new standards proved to be very similar. This was not entirely unexpected, but it helps the future work to have the differences compiled in one place.

|

|

|

|

|

|

-As can be seen in \autoref{tab:initial_measurements} and \autoref{tab:initial_measurements_cna}, some values exceeded the limits (marked in red). Three of these values even exceeds the old standard's limits, thus indicating that the equipment should probably be usable with the new standard after some service or calibration. With this in mind, the course of the project will be targeted towards the design of an automated verification system, as described in \autoref{sec:planning}. With such a verification equipment at hand, the calibration of the generators might be easier to perform as well.

|

|

|

+%%%%%%%%%%%%%%%%%%%%%%%%

|

|

|

+\subsection{Examination and initial measurement of the old equipment}

|

|

|

+As can be seen in \autoref{tab:initial_measurements} and \autoref{tab:initial_measurements_cna}, some values exceeded the limits (marked in red). Three of these values even exceeds the old standard's limits, thus indicating that the equipment should probably be usable with the new standard after some service or calibration. With this in mind, the course of the project was targeted towards the design of an automated verification system. With such a verification equipment at hand, the calibration of the generators might be easier to perform as well.

|

|

|

|

|

|

-\section{Method}

|

|

|

+%%%%%%%%%%%%%%%%%%%%%%%%

|

|

|

+\subsection{Test architecture}

|

|

|

+The chosen architecture, with the embedded attenuators, proved to be difficult to implement because of the high frequency design involved. In the future, it might be better to develop a more manual procedure using off the shelf attenuators and a check list. It might be possible to automate the analysis of the results even if the connection of the verification equipment must be made automatically.

|

|

|

+

|

|

|

+%%%%%%%%%%%%%%%%%%%%%%%%

|

|

|

+\subsection{Design of dummy loads}

|

|

|

+The results are well within the \SI{1}{\percent} specified by the standard \cite{iso_7637_2}. During tests with the assembled dummy load it seems to work and does not become warm, which indicates that the number of resistors is good or even excessive.

|

|

|

|

|

|

-It was suprisingly difficult to find and choose apropriate components for the dummy load. The resistors had to tolerate extreme surges and the relays had to have high insulation voltages between the contacts. Even finding the encapsulation for the relay box proved to be a challenge, since the filtering options available at the retailers web stores were not always consistent.

|

|

|

+%%%%%%%%%%%%%%%%%%%%%%%%

|

|

|

+\subsection{Design of the switching fixture and the embedded attenuators}

|

|

|

+The attenuators were not populated with compensation capacitors. The results are, in the attenuators current state, not feasible for usage in calibrating the equipment. The required bandwidth for the attenuators must be \SI{400}{\mega\hertz} or greater. The simulated results indicated that this would be the case and that the attenuators will need compensation. But since the actual parasitics in the PCB traces and the design in whole is difficult to know beforehand, the capacitors were left out to start with.

|

|

|

|

|

|

-The usage of the energy curve in the datasheet might have been wront \todo[explain interval, not absolute time. All intervals must be checked.]

|

|

|

+The measured results were pretty unstable and difficult to correlate to the simulated results. Therefore, it is improbable that the compensation capacitors used in the simulation would help in the real world case, at least not with the simulated values. There was no time left in the project to experiment with this.

|

|

|

+

|

|

|

+%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

|

|

|

+\section{Method}

|

|

|

+The methods that need further explanation and reflections are presented here.

|

|

|

|

|

|

+%%%%%%%%%%%%%%%%%%%%%%%%

|

|

|

+\subsection{Components}

|

|

|

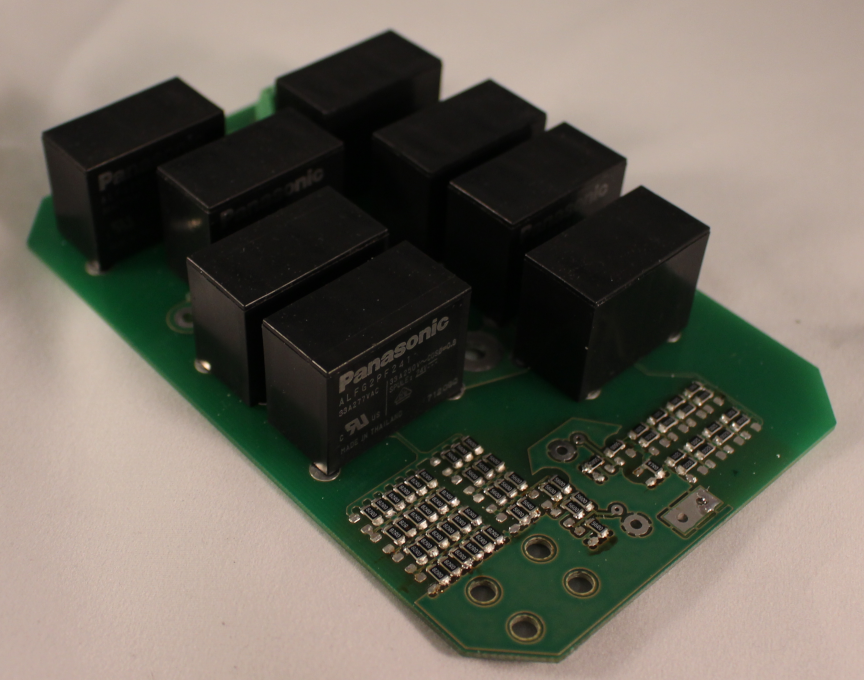

+It was surprisingly difficult to find and choose the appropriate components for the dummy load. The resistors had to tolerate extreme surges and the relays had to have high insulation voltages between the contacts. Even finding the encapsulation for the relay box proved to be a challenge, since the filtering options available in the retailer's web stores were not always consistent.

|

|

|

|

|

|

-\subsection{Dummy Loads}

|

|

|

-The results are well within the \SI{1}{\percent} specified by the standard \cite{iso_7637_2}.

|

|

|

+The usage of the energy curve in the datasheet might have been wrong. In this work, the total accumulated energy from time $t=0$ was considered, but a more reasonable approach would be to test all starting points to find the most extreme energy curve.

|

|

|

|

|

|

-\subsection{Attenuators}

|

|

|

+%%%%%%%%%%%%%%%%%%%%%%%%

|

|

|

+\subsection{Design of attenuators}

|

|

|

\label{discussion_attenuators}

|

|

|

-During the project, the attenuation was considered as the voltage attenuation \mbox{$att = 20 log_{10}\left( \frac{V_{in}}{V_{out}} \right) \si{\deci\bel}$}. However, lots of information and many tools for RF applications, including the calculator used for the attenuators in this project, assume power attenuation \mbox{$att = 10 log_{10}\left( \frac{P_{in}}{P_{out}} \right) \si{\deci\bel}$}. The result of these two properties coincides when the input and output impedance, as well as the driving and loading impedance, are all the same.

|

|

|

+During the project, the attenuation was considered as the voltage attenuation \mbox{$att = 20 \times log_{10}\left( \frac{V_{in}}{V_{out}} \right) \si{\deci\bel}$}. However, the online calculator used was using power attenuation \mbox{$att = 10 \times log_{10}\left( \frac{P_{in}}{P_{out}} \right) \si{\deci\bel}$}. The two different ways of expressing attenuation will give the same result if the input impedance is equal to the output impedance. The derived expression seen in \autoref{equ:db-calc}. So to use the online calulator for the \SI{1000}{\ohm} attenuator one would have to specify that you want $\SI{60.1}{\deci\bel}+10 \times log_{10} \left( \frac{50}{1000} \right) \approx \SI{47.1}{\deci\bel}$. However, this was not known at the time and the values were tweaked manually in LTSpice until the desired attenuation was achieved, but the output impedance was not considered during the tweaking and thereby ended up being a bit mismatched for the next $\Pi$ link.

|

|

|

|

|

|

-The fact that these two ways of expressing attenuation could be mixed up was not noticed until very late in the project. Thus the values provided by the online attenuator tool did not give the desired results in the simulator, for the \SI{1000}{\ohm} attenuator. This was at the time manually tweaked until the desired attenuation was acquired, but the out impedance was not considered during the tweaking and thereby ended up being a bit mismatched for the next $\Pi$ link.

|

|

|

+\begin{equation}

|

|

|

+\begin{split}

|

|

|

+\label{equ:db-calc}

|

|

|

+Power~attenuation = 10 \times log_{10}\left( \frac{P_{in}}{P_{out}} \right) = 10 \times log_{10}\left( \frac{ \frac{U^2_{in}}{R_{in}} }{ \frac{U^2_{out}}{R_{out}} } \right) =\\

|

|

|

+=10 \times log_{10} \left( \left( \frac{U_{in}}{U_{out}} \right)^2 \times \frac{R_{out}}{R_{in}} \right) = 20 \times log_{10} \left( \frac{U_{in}}{U_{out}} \right) + 10 \times log_{10} \left( \frac{R_{out}}{R_{in}} \right)

|

|

|

+\end{split}

|

|

|

+\end{equation}

|

|

|

|

|

|

There are infinitely many constellations to approximate the nominal value, in this project it was tried to use as few resistors as possible. This process was performed manually, since no suitable software for solving the problem was found. Thus the chosen constellations might not be optimal.

|

|

|

|

|

|

+%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

|

|

|

+\section{Source criticism}

|

|

|

+Many of the sources are standards from ISO or information from their website. This information can be considered trustworthy since they are the authors of the standards.

|

|

|

|

|

|

-\subsection{Desired vs implemented (simulation)}

|

|

|

-Parasitic effects. (real life, back to simulation)

|

|

|

+The technical note from AVX is based on their own practical experiments, but has no references to any other work. There is a possibility that the methods used were inappropriate or that the results are wrong. They are, however, a manufacturer of capacitors and thus it should be in their interest to have accurate information. The only information used from this, is one of the parasitic values of the resistors, so even if the values are wrong the impact can not be very big.

|

|

|

|

|

|

-\section{The work in a wider context}

|

|

|

-Ethical aspects

|

|

|

+The same reasoning can be made for the technical note from Vishay. Since they are a manufacturer of resistors they should have accurate information.

|

|

|

+

|

|

|

+The book \emph{High-speed digital design} seems to be widely used.

|

|

|

|

|

|

-\section{References}

|

|

|

-Source critisism

|

|

|

+The book \emph{The circuit designer's companion} doesn't seem to be as widely used, but it is the third edition and can hopefully be considered mostly correct after two revisions.

|

|

|

+

|

|

|

+%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

|

|

|

+\section{The work in a wider context}

|

|

|

+Test equipment and methodologies can be a very sensitive topic. When a company wants to put a product on the market, they will need to bring their product to a test lab to conduct these tests according to the relevant standards. If the test procedure is wrong, or leaves too much space for interpretations, it could lead to a product failing the test even though it should have passed if the test was made in another lab. Or even worse, an unsafe product might be put on the market due to being falsely passed in the tests. There is always a chance for errors, but using well designed automated systems for testing and verification mitigates the human errors which are the most unpredictable.

|

|

|

|

|

|

%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%%

|

|

|

%%% lorem.tex ends here

|